Method Statement for the erection of precast & prestressed elements.

Purpose.

The aim of this method statement is to describe the

procedure that will be adopted for erection

of Precast and Pre-stressed

concrete Elements. The process include detailed design, workshop

drawings, Sequence of work, Quality Control System, Tolerances, Risk involved

and risk controls, Housekeeping, to be adopted during the erection of Precast

and Pre-stressed Concrete Elements.

Pre-construction activities.

Before commencing, precast subcontractor shall obtain the

necessary approval for the

subcontractor/applicator and their proposed material.

Ensure to obtain the approvals for the detailed shop drawings

for the sub-structure raft foundation with all related drawings.

Ensure that this Method statement with risk assessment is

approved by the Consultant.

Construction activity.

General.

Erection shall be done by Mobile crane with sufficient

capacity. Precast/prestressed concrete elements shall be lifted from the

lifting anchor provided. Proper tools and lifting sling and safe device shall be used for

lifting.

Before starting erection, a survey of the area to receive

Precast/prestressed concrete segments shall

be done to monitor any difference in dimensions or levels exceeding the

tolerances.

Precast/prestressed concrete segments will inspect before

the erection by subcontractor Erection Engineer /Supervisor and Engineer.

Transportation and delivery to site.

Precast/prestressed concrete elements shall be transported

to the site only after the QC final

inspection and Approval.

Precast/prestressed concrete Elements shall be transported

to site on a flatbed trailer, Low bed

trailers and “A” frame trailers

generally standard 12 -15-meter length. Elements will be supported over the trailer by special belt or steel

chain fixed to the trailer. Wooden wedges/polystyrene bottom and side support will be provided to

eliminate breakages if required.

Loading, transportation & offloading shall be done

carefully to avoid any major damage to the

precast elements.

Offloading and loading of panels should be done using

suitable mobile crane and elements shall be

stacked in steel racks as per standards.

Suitable lifting devices/sling/equipment will be used for

loading and off-loading of the elements. Crane will be used for loading and

off-load of the Precast/prestressed concrete Segments. Capacity of crane shall be decided depending on the

weight of the elements and boom length required.

Barricade to be provided and sign boards to be placed in the

area of lifting to avoid unauthorized personnel entering to the lifting area.

While the Precast/prestressed concrete elements are being

lifted for loading or off-loading, proper

signboard will be kept if the operation time is more, or a competent

person will be directing the people away

from the crane boom (when the operation time is short).

If Precast/prestressed concrete Elements are stored at site,

it should be as close as possible to crane

to avoid double handling.

The access road should be prepared by main contractor to

receive trailers transporting the

Precast/prestressed concrete units.

All the precast Precast/prestressed concrete Elements will

be delivered to the site as per the sequence

required to ensure the continuous erection.

Field survey.

A field survey and stakeout of existing cast in situ

dimension will be performed to permit accurate placement of Precast/prestressed

concrete elements. Before the erection of Precast/prestressed concrete elements

is started the surveyor will verify by

accurate field measurements, location (orientation, level) of bearing pads,

M&E service accessories etc.

The exact position of all works will be established by the

main contractor from control points, which are shown on the panels and in the conjunction and as agreed

with the Engineers surveyors

Grid lines should be handed over by Main Contractor for each

zone and benchmark level.

Survey also should be done for the dowel bars connecting the

panels to the slabs .

Level of slabs or rafts should be within the tolerance ( zero gap to max of 30

mm between panels & slab and rafts),

if exceeds special materials shall be used.

All computations and drawings necessary to establish the

exact positions of the work will be neatly made and will be made available to

the Engineer for review and approval.

Scaffolding and temporary work.

Precast elements prior and upon placing in their final position,

will be securely supported and anchored. If necessary, suitable, and safe

working platforms will be provided in all locations required to allow clear and

easy approach of the workers to produce quality connection details. Scaffolding

placing will be closely coordinated with the main contractor to ensure

accessibility to other areas of work.

Scaffolding will be used mainly for the temporary supported or alignment of the panels or in case of grouting finishing or elements fixing.

Ladders may be used in some conditions (ex-Grouting, etc.)to

assure easy access specially inside the small rooms.

Erection.

Erection of precast column of foundation.

Typical sketch for lifting &erection of precast column

in attached Lifting and Erection drawings.

CAST INSITU foundation shall be done as per the approved

drawing. Starter bar diameter, location

shall be as approved drawing.

Precast column will be placed on CAST INSITU foundation,(T20

dowel from CIS foundation will be insert into 50mm corrugated hole pipe of

precast concrete element)

While precast column erected it shall be supported by push

pull prop jacks as per attached propping design.

Precast Column alignment shall be done, and line ,level

,verticality, and straightness shall be maintained as per the approved erection

layout.

Grout the 50mm corrugated hole pipe by approved non shrink

grout.

All exposed areas should be thoroughly cured in an accepted

and approved manner.

Erection of precast beam.

Typical sketch for lifting &erection of Precast column& beam in attached Lifting and Erection

drawings.

Precast beam will be placed on precast column as per

attached propping details &design.

Alignment of the beam shall be done to maintain the line

,level ,straightness and verticality.

Cast in-situ steel reinforcement shall be provided as per

the approved steel reinforcement drawing.

Apply the concrete

for balance portion of beam. Grade of concrete strength shall be as per project

specification for super structure.

Curing shall be continued as per the project

specification/standards.

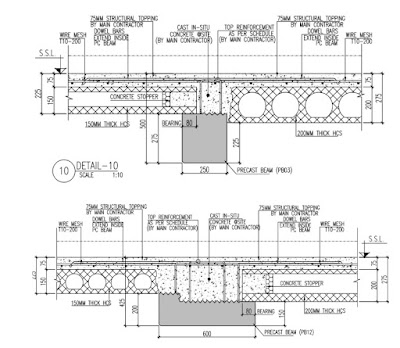

Erection of slab(hollow core/ form slab).

Typical sketch for lifting &erection of slab in attached

Lifting and Erection drawings.

Hollow core Slabs

will be placed on beam CIS retaining wall corbel as per attached details

&design.

Precast form slab will be placed on precast beam as per

attached propping details &design.

Maintain the minimum bearing as per drawings &design.

Alignment of the slab shall be done to maintain the line

,level, straightness, and verticality.

Cast in situ Steel reinforcement shall be provided as per

the approved steel reinforcement drawing and below connection details.

Apply the concrete for topping of Slab. Grade of concrete

strength shall be as per project specification

for super structure.

Curing shall be continued as per the project

specification/standards.

Repairing.

Repairing works for any general defects in precast

/prestressed concrete elements shall be done using approved repair materials or

any equipment approved material. Repairs will be carried out as per the

manufacturer recommendations.

See Risk Assessment Template for Delivery and Erection Precast Elements.

See Checklist Template of Erection Precast/ Prestressed Concrete Elements.