Method Statement for installation External Insulation & Finishing System (EFIS).

INDEX.

1. PURPOSE.

2. SCOPE OF WORK.

3. METHODOLOGY.

1.0 PURPOSE

The purpose of this Method Statement is to give the outline

of each activity we are intending to

execute on site, to identify the risk associated during the installation of the

External Insulation & Finishing

system (EFIS), and to identify the

control system to ensure full compliance to the approved Shop Drawings as

well as the Contract

specifications.

2.0 SCOPE OF WORK

The scope of this method statement is to define the

procedure that will be followed for Supply and application of External Insulation

& Finishing system (EFIS).

3.0 Methodology

The area where the EIFS installation will be done shall be

inspected, marked on the drawings, the structure and agreed upon in terms of

area as well as extent of the system to be installed.

The surfaces agreed for the installation of EIFS shall be

accepted free from mortar, snorts, loose concrete, rebars and ties, tie holes,

oil, grease, friable matter, curing compounds, coatings, markings, surface

cracks, structural defects including off alignments or any other matter that

shall hamper the flawless installation of the system in any way.

Main Contractor must provide Civil & MEP clearance or

any interfacing activity clearance as well as area hand over certificate to

PFC, prior to commencement of EIFS works.

Installed scaffolding platforms are to be made available in

position to access the substrate safely and easily to facilitate the

installation of the EIFS in line with the site Safety Regulations. A clear gap

of 400 mm between scaffolding and substrate is mandatory and to be maintained

as tooling space to carry out the work. If the gap is less than this it would

affect the work as well as the quality Survey.

Prior to any installations it is mandatory to survey to

ensure planarity of the substrate. This is achieved by putting level buttons at

various points of the substrate.

Nylon string lines are fixed from top to bottom over the

level buttons to determine the planarity of the surface thereby estimating the

thickness of the insulation board required on specific areas.

3.1. SURFACE PREPARATION:

The surface should be clean, dry, and sound. The treatments recommended for the system

symptoms are given below.

SYSTEM

SYMPTOM

|

TREATMENT

|

Damp

|

Rectify

causes and allow drying out.

|

Dusty / Dirty

|

Brush down,

pressure clean and prime with approved material

|

High Porosity

(AAC Blocks)

|

Seal the

substrate by approved material

|

Efflorescence

|

Brush down

and prime with approved material

|

Mortar Lumps

|

Remove mechanically.

|

Grease,

shutter oil remains

|

Steam clean,

using detergent additives. Wash off again with water.

|

Render with

damaged areas

|

Remove loose

render; fill holes and repair the surface where required with approved

material

|

Peeling

Coatings

|

Remove old

coating, pressure clean and prime with approved material

|

NOTE: Mineral wool

EIFS insulation cannot be rasped level! – substrate level assessment is

critical mineral wool insulation EIFS systems: (unlike eps EIFS systems)

undulations in mw insulation boards cannot be rasped level at board

installation stage. As a result, correct

installation/ inspection of the levelness of the substrate wall is critical to

ensure that the finished EIFS system does not have undulations in the

finish.

For acceptable substrate

tolerance levels see EIFS manufacturer document “evaluation of substrates and

EIFS finishes/acceptable tolerance”. If maximum levelness tolerances are not

met, agreement must be made in writing with design team/main contractor &

EIFS sub-contractor on the remedy prior to EIFS start mineral wool board installation.

3.2. PRIMING OF MINERAL WOOL INSULATION BOARDS (PRIOR TO ADHESIVE FIXING).

Check the quality of board surface and if

necessary, apply the primer as per manufacture recommendation on the flat side

of the boards to consolidate the surface. (Please note that

when applying primer, the boards should be in the upright position). Allow the

primed boards to dry overnight.

3.3. ADHESIVE FIXING OF MINERAL WOOL INSULATION BOARDS:

Recommended dimension of the Mineral Wool Insulation

board: 0.6 m x 1.2 m. Mineral Wool is to

be non-combustible & manufactured in compliant with local regulations &

Euro class A1 of BS EN 13501-1 or ASTM E 136.

Level Substrate (Method 1. Notched

Trowel) Uneven Substrate up to 10mm. (Method 2. Ribbon and dab)

Used adhesive between masonry

substrate & MW (Mineral Wool insulation boards) as per material

recommendation. Allow the material to stand for about 5 minutes, remix &

use. Mix only enough material for immediate use to avoid wastage.

Following Mineral wool board

priming application, apply 1 coat of mortar adhesive to the Mineral wool board

using a 10 mm notched trowel in a downward direction at 90 º angles over entire

board and immediately fix the board against the substrate and allow to dry

overnight. DO NOT MAKE BEAD AROUND BOARD EDGE.

Mineral Wool Insulation board edges

should be kept adhesive free to prevent thermal bridging.

Fix insulation boards in staggered

pattern (running bond) and ensure all outside and inside corners are

interlocked. Offset insulation board’s joints 200 mm or more from the corners of

openings around doors, windows, or other similar conditions. Ensure that all opening corners are cut

(L-shape) from one piece of board. Insulation boards must not bridge expansion

joints in masonry or concrete substrates.

Install a movement/expansion bead if such joints present.

Fix insulation board as per

adhesive method. Ensuring boards are level (use plumb line / spirit level/

2-meter straight edge).

Back wrapping with reinforcing

fiberglass mesh and embedding mortar is recommended for all insulation boards

at system terminations (end reveals / openings) to reinforce the edges and also

prevent water ingress.

Allow board Adhesive

to dry for 24 hours.

Avoid gaps between Mineral wool

boards (Do not fill gaps with base coat) In event of gaps< 5 mm -fill with

strips of cut Mineral wool and trim level with MW board surface.

Co-ordinate for the approval of

Mineral Wool board installation levels prior to mechanical fixing.

3.4. MECHANICAL FASTENERS/DOWELS INSTALLATION OF MINERAL WOOL BOARDS.

EIFS system is

designed as a mechanical fixed with supplementary adhesive.

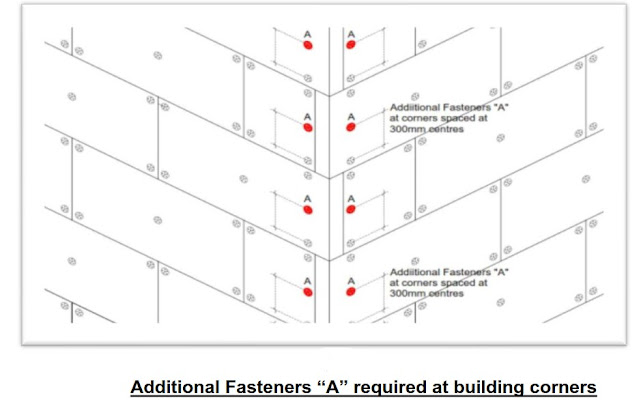

EIFS Mechanical Fasteners

are fixed directly through the un-coated board after a minimum of 24 hours – see

Figure A for location of fasteners per board (5 numbers per board) See Figures

B, C for additional fasteners around window openings and corners.

EIFS Mechanical

Fasteners (PP dowel with PP - PA nail)

should penetrate a

minimum of 4 cm

into concrete, solid concrete, and hollow concrete block substrates. Mechanical

fasteners should penetrate a minimum of 7 cm into the AAC / ALC substrates to

secure anchorage.

Ensure dowel heads

are level with the insulation boards to prevent bumps in the final finish.

Four EIFS Fasteners

at the corners & one fastener in the center of each board (for board of size

0.6 m x 1.2 m) and additional fasteners around windows/doors/openings and corners

as indicated in figure B, C.

3.5. CORNER PROFILES & DIAGONAL STRESS PATCH MESH.

For corners, window lintels and

column edges; EIFS Aluminum corner beads or alternatively

EIFS Plastic corner beads with fiberglass wing

mesh (10 cm x 10 cm) are used at all

corners/opening to protect edges

from impact and to achieve consistently straight edges. Fix windows reveal beads as required.

Fix diagonal Stress patch mesh on all

corners as indicated in Fig D below and overlap with corner bead mesh

to prevent cracks at corners.

3.6. CONTACT AREAS - BASE-COAT APPLICATION & FIBERGLASS MESH:

CONTACT AREAS - For areas up to 2 m

height from ground level.

Apply 1 coat of a solution on the entire surface of the fixed mineral

wool boards.

Apply 1st coat of base-coat by

trowel to an approximate thickness of 2 mm and immediately embed the 160 g/m2

fiber glass mesh into surface by troweling from center out to avoid any

wrinkles. Overlap all fiber glass mesh edges

by 10 cm. Level with a 60 cm scraper

without sprinkling water on the surface.

Allow the first layer of adhesive overnight

drying time before applying the second layer.

Following drying of 1st coat

lightly dampen the dried first coat of base-coat with water using a crop

sprayer; then apply the second layer.

Apply 2nd coat of base-coat by

trowel to an approximate thickness of 2 mm and immediately embed the 160 g/m2

fiber glass mesh into the surface by troweling from the center out to avoid any

wrinkles. Overlap all fiber glass mesh

edges by 10 cm. Level with a 60 cm scraper without sprinkling water on the

surface. Allow the second layer 12 – 16

hours drying time before applying the third layer.

Following drying of 2nd coat,

lightly dampen the dried second coat of base-coat with water using a crop

sprayer. Apply 3rd coat of base-coat by

trowel at 1 mm to 1.5 mm thickness. Ensure the full cover of the mesh and level

off with a 60 cm scraper without sprinkling water on the surface.

3.7. NON-CONTACT AREAS - BASE-COAT APPLICATION & FIBERGLASS MESH

NON-CONTACT AREAS –

Areas 2 m height above ground level (and above) & areas not accessible

to public or as

per project building requirements.

Apply 1 coat of

solution on the entire surface of the fixed mineral wool boards prior to

application base-coat.

Apply 1st coat of base-coat by trowel to an approximate thickness of 2 mm and

immediately embed

the 160 g/m2 fiber glass mesh into the surface by troweling from the center out

to avoid any wrinkles. Overlap all fiber

glass mesh edges by 10 cm. Level with a 60 cm scraper without sprinkling water on

the surface.

Allow the first

layer of base-coat overnight drying time before applying the second layer.

Following drying

of 1st coat lightly dampen the dried first coat of base-coat with

water using a crop

sprayer; then apply the second layer.

Following drying

of 2nd coat, lightly dampen the first coat of base-coat with water using a crop

sprayer. Apply 2nd & final coat of base-coat by trowel at 1 mm to 2 mm thickness.

Ensure the full cover of the mesh and level off with a 60 cm scraper

without sprinkling water on the surface.

Total thickness should be 3 mm-4 mm.

Co-ordinate for

the approval of base-coat levels prior to solution

application.

Note. It is important to

prevent water ingress behind the EIFS. Therefore, special care should be taken

to treat all gaps between system & walls especially above window & door

heads, beneath window & door sills, sides of windows & doors, at roof

/wall intersections, abutments of lower walls with higher walls, projecting

features & base of the walls etc. Fill in the gaps with low expansion PU

foam, cut back and seal with appropriate exterior grade fire rated sealant. A

better option would be to fix suitable aluminum

3.8. DECORATIVE FINISH:

Rollers apply 1

coat of primer and allow to dry.

Apply 1 coat of TEXTURE

COATING (as per approved texture & color) to

a thickness of 1.5 –

2 mm and allow to dry.

Note:

Application should

not be done at very low or high temperatures (< 5 c or ≥40 c) and/or in very windy conditions.

Plans work accordingly.

Do not apply if rain

is expected over the next 24 hours.